Best Info About How Many KW Is 3-phase

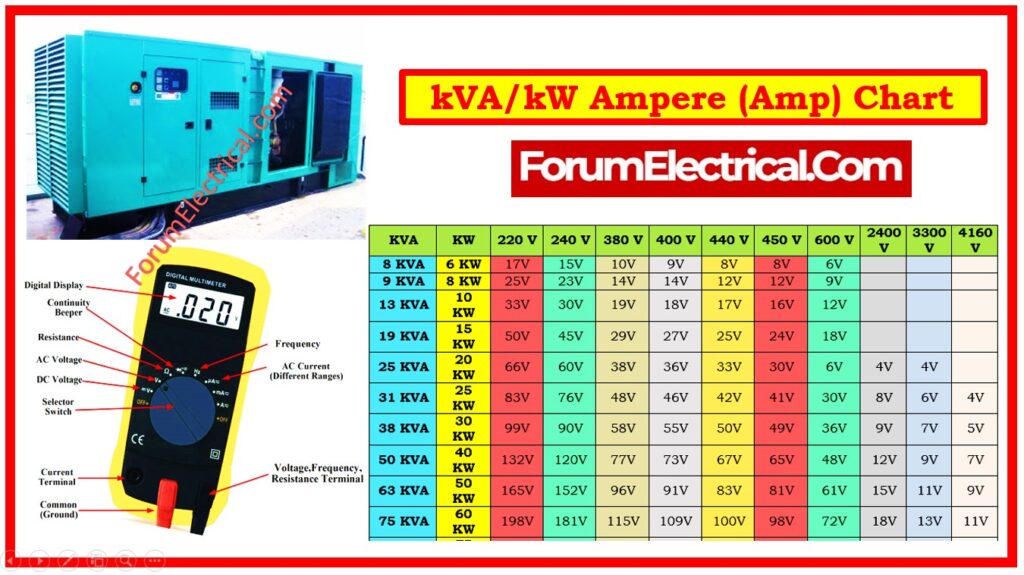

KVA/kW Ampere (Amp) Chart

Unlocking the Power of Three

1. Understanding 3-Phase Power

Ever wondered what all the fuss is about 3-phase power? It's not some secret society handshake, but rather a clever way to deliver electricity more efficiently. Think of it like this: instead of one guy pushing a swing (single-phase), you've got three people working together, each pushing at slightly different times (3-phase). This results in a smoother, more consistent power delivery, especially crucial for heavy-duty equipment and industrial applications. The 'how many kW is 3-phase' question ultimately boils down to the specific voltage and current involved.

Now, kW (kilowatts) is simply a measure of real power — the power actually used to do work. It's like the amount of effort those swing-pushers are putting in. With 3-phase, we need to consider the voltage between the lines, the current flowing through them, and a little something called the power factor, which accounts for any inefficiencies in the system. Don't worry, we'll break it down further, no electrical engineering degree required!

Imagine a bustling factory floor. You'll see massive machines whirring, conveyor belts churning, and robotic arms swinging. These kinds of operations often rely on 3-phase power because it's better equipped to handle the high power demands. Single-phase, like what you have in your home, might struggle or even overheat under such a load. Think of it as trying to run a marathon on a single slice of toast you'd probably run out of steam pretty quickly. 3-phase power provides the "fuel" needed to keep these industrial giants going strong.

Essentially, the benefit of 3-phase power is about distributing the load. Instead of all the power concentrated in a single circuit, it's spread across three, resulting in smoother and more consistent power. This reduces stress on the power grid, minimizing voltage dips and keeping everything running optimally. This is why industrial settings often lean towards 3-phase for high power needs.

The Formula

2. Decoding the Power Equation

Alright, let's dive into the math (but don't worry, it's not as scary as it sounds!). The formula for calculating 3-phase power in kW is: kW = (3 V I PF) / 1000, where:

V is the line-to-line voltage (in volts). This is the voltage measured between any two of the three phases.

I is the current (in amps) flowing through the lines.

PF is the power factor (a decimal between 0 and 1). This represents the efficiency of the electrical system. An ideal power factor is 1, but in reality, it's often lower due to inductive loads like motors.

The 3 is the square root of 3, approximately 1.732, and it's there because of the 3-phase nature of the system. And we divide by 1000 to convert from watts to kilowatts.

Let's imagine we have a 3-phase system with a line-to-line voltage of 480V, a current of 50A, and a power factor of 0.8. Plugging these values into our formula, we get: kW = (1.732 480 50 0.8) / 1000 = 33.25 kW. So, this system is delivering approximately 33.25 kilowatts of real power.

The power factor is a crucial element. A lower power factor means a less efficient system. Utilities often charge more for low power factors because it puts a strain on their infrastructure. Improving the power factor can lead to significant cost savings and a more stable electrical system. Its like making sure the swing-pushers are all pushing in sync, maximizing the swing's momentum.

Amps To Kilowatts (kW) Conversion Calculator Asutpp

Examples of 3-Phase kW Requirements

3. From Factories to Data Centers

So, where do we typically see significant 3-phase kW demands? Let's consider a few examples:

Manufacturing Plant: A large manufacturing plant with heavy machinery, such as motors, pumps, and compressors, can easily draw hundreds or even thousands of kW. The exact amount depends on the size of the plant, the type of equipment used, and the production volume. These facilities depend on consistent power, so they are likely using 3-phase power.

Data Center: Data centers, packed with servers and cooling systems, are notorious power hogs. A medium-sized data center might require several hundred kW, while larger facilities can demand multiple megawatts (MW). They require continuous, stable power to ensure uninterrupted operation, making 3-phase an absolute necessity.

Large Commercial Buildings: Office buildings, shopping malls, and hospitals often utilize 3-phase power for their HVAC systems, elevators, and other high-power equipment. The specific kW requirement depends on the building's size, occupancy, and the types of equipment installed. Its all about keeping things running smoothly and comfortably for everyone.

Electric Vehicle (EV) Charging Stations: Fast-charging EV stations, especially those designed for commercial fleets, can draw significant power. A single fast charger can require 50 kW or more, and charging stations with multiple chargers can demand hundreds of kW. 3-phase power is essential for these high-power charging applications. Imagine a fleet of electric buses needing to "refuel" quickly 3-phase ensures they're back on the road with minimal downtime.

Cara Menghitung Ampere Mcb 3 Phase Pt Wimar Digital N Vrogue.co

Factors Influencing 3-Phase kW Needs

4. More Than Just Voltage and Current

Calculating the theoretical kW is one thing, but several factors can influence the actual power consumption in a 3-phase system:

Equipment Efficiency: The efficiency of the equipment connected to the system plays a significant role. Less efficient equipment will draw more power to perform the same task. It's like comparing a gas-guzzling car to a fuel-efficient hybrid — both get you from point A to point B, but one uses a lot more energy.

Load Balancing: Ideally, the load should be evenly distributed across all three phases. An unbalanced load can lead to increased current draw on some phases and decreased efficiency. It's like having one person on the swing pushing much harder than the others — it's not very efficient.

Power Factor Correction: As mentioned earlier, a low power factor reduces the effective power delivered by the system. Implementing power factor correction techniques, such as installing capacitors, can improve the power factor and reduce the overall kW demand.

Demand Management: Implementing demand management strategies, such as staggering the use of high-power equipment, can help reduce peak demand and lower overall energy consumption. This involves analyzing the system's usage patterns and implementing changes to optimize performance. This is like making sure you dont run all your appliances at the same time to avoid tripping the breaker.

Environmental Conditions: Environmental conditions, such as temperature and humidity, can also affect the power consumption of certain equipment. Motors, for example, may draw more current when operating in hot environments. Its like how your cars fuel efficiency decreases when youre blasting the AC on a scorching summer day.

Handwolf Blog

Optimizing Your 3-Phase System for Efficiency

5. Saving Energy and Money

So, you've got a 3-phase system — how can you make it more efficient? Here are a few tips:

Regular Maintenance: Regular maintenance of electrical equipment, such as motors and transformers, can help ensure they are operating at peak efficiency. This includes lubricating moving parts, cleaning cooling fins, and checking for loose connections.

Upgrade to Energy-Efficient Equipment: Replacing older, less efficient equipment with newer, energy-efficient models can significantly reduce power consumption. While the initial investment may be higher, the long-term savings can be substantial. It's like upgrading to a more fuel-efficient car — you'll save money on gas in the long run.

Power Factor Correction: Installing power factor correction capacitors can improve the power factor and reduce the overall kW demand. This not only saves money on energy bills but also reduces stress on the electrical grid.

Load Balancing: Ensure that the load is evenly distributed across all three phases to minimize imbalances and improve efficiency. This may involve rearranging equipment or installing additional wiring.

Energy Monitoring: Implementing an energy monitoring system can provide valuable insights into power consumption patterns, allowing you to identify areas where energy is being wasted and implement targeted improvements. Its like having a fitness tracker for your electrical system, helping you track your energy use and set goals to improve.