Looking Good Info About Can You Splice Multiple Wires Together

Three Wire Splice

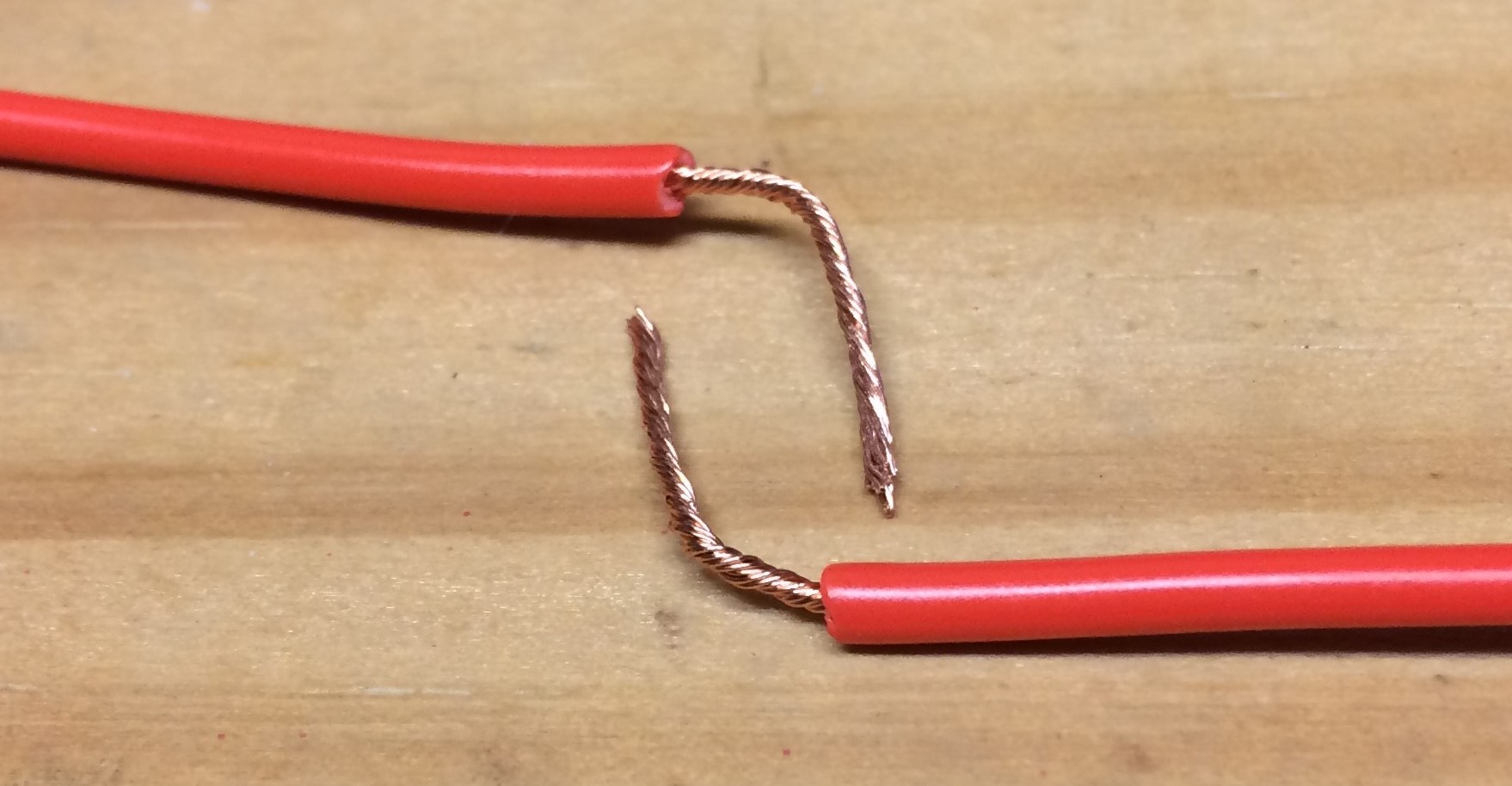

Splicing Multiple Wires

1. Understanding Wire Splicing Basics

So, you've got a project — maybe you're wiring up some snazzy new lights, or perhaps you're adding an outlet in your garage. Either way, you've encountered the inevitable question: "Can I splice multiple wires together?" The short answer is, yes, absolutely! But, and this is a big but, it's crucial to do it correctly and safely. After all, electricity isn't something to play around with lightly (pun intended!).

Think of it like this: wiring is like plumbing for electricity. You need solid connections to ensure everything flows smoothly and nothing leaks (or, in this case, sparks!). A bad splice can lead to all sorts of problems, from flickering lights to, well, potentially much more serious issues. That's why understanding the fundamentals of wire splicing is paramount.

First things first, let's clarify what splicing even means. In simple terms, it's joining two or more wires together to create a continuous electrical path. This is essential when you need to extend a wire, create a branch circuit, or repair a damaged wire. The key is to create a connection that's both mechanically strong (so it doesn't pull apart) and electrically sound (so it conducts electricity efficiently).

Before you even think about touching those wires, make sure the power is OFF! I can't stress this enough. Flip the breaker, double-check it with a non-contact voltage tester, and then check it again. Seriously. Consider it the electrician's equivalent of washing your hands before dinner — essential hygiene.

2. Choosing the Right Splicing Method

Okay, so you're ready to get splicing. But hold on a second! There are several different methods you can use, and the best choice depends on the specific situation. Let's take a look at some of the most common options.

Wire connectors (also known as wire nuts) are probably the most widely used method, especially for joining wires inside electrical boxes. They're simple, relatively inexpensive, and pretty darn reliable. You just strip the ends of the wires, twist them together (or keep them parallel, depending on the connector type), and screw the connector on. Make sure you choose the right size connector for the number and gauge of wires you're connecting — the packaging will usually have a handy chart.

Another option is using crimp connectors. These are small metal sleeves that you slide over the stripped ends of the wires and then crimp down using a special crimping tool. Crimp connectors are great for creating strong, permanent connections, especially in situations where vibration might be an issue. They're often used in automotive wiring and other applications where reliability is crucial.

For certain applications, like splicing wires in a damp or outdoor environment, you might want to consider using waterproof connectors. These connectors are designed to seal out moisture and prevent corrosion, ensuring a long-lasting and reliable connection. They typically involve some kind of gel or sealant that protects the wires from the elements.

3. Safety First

Alright, you've chosen your splicing method and you're itching to get started. But before you grab those wire strippers, let's talk about safety. Remember, electricity is a powerful force, and it deserves respect. Cutting corners can lead to serious consequences, so it's always better to err on the side of caution.

Always, always, always use the right tools. Don't try to strip wires with a pocket knife or crimp connectors with pliers. Invest in a good pair of wire strippers, a crimping tool, and any other specialized tools you might need for your chosen splicing method. These tools are designed to make the job easier, safer, and more reliable.

Pay close attention to wire gauge. Wire gauge refers to the thickness of the wire, and it's crucial to match the wire gauge to the circuit's current-carrying capacity. Using a wire that's too thin can cause it to overheat and potentially start a fire. The amperage rating of the circuit will determine the appropriate wire gauge to use. If you're not sure, consult a wiring chart or ask an electrician.

After you've made the splice, give it a good tug to make sure it's secure. If the wires pull apart, it's a sign that the connection isn't strong enough. Re-do the splice, making sure to strip the wires properly and use the correct technique. And never, ever, leave exposed wires hanging out — that's just asking for trouble. Always cover splices with electrical tape or place them inside an approved electrical box.

4. Common Mistakes to Avoid When Splicing Wires

Even experienced DIYers can make mistakes when splicing wires. Here are a few common pitfalls to watch out for:

Stripping too much insulation. This leaves exposed wire that can potentially short circuit to other wires or metal surfaces. Only strip enough insulation to make a good connection, typically about 1/2 to 3/4 of an inch.

Not tightening wire connectors enough. A loose connection can create resistance, which can cause the wires to overheat and potentially melt the connector. Make sure to tighten the connector securely, but don't overtighten it, as this can damage the wires.

Mixing different metals. Avoid splicing copper wires to aluminum wires directly, as this can cause corrosion and lead to a poor connection. If you need to join copper and aluminum wires, use a special connector that's designed for this purpose.

Ignoring local electrical codes. Electrical codes are in place to ensure the safety of your home and family. Before you start any wiring project, familiarize yourself with the local codes in your area. These codes may specify certain wiring methods, materials, and installation requirements.

5. Troubleshooting Spliced Wires

Sometimes, even if you've followed all the best practices, things can still go wrong. If you're experiencing problems with your spliced wires, here are a few troubleshooting tips:

Check for loose connections. A loose connection is the most common cause of problems with spliced wires. Give each connection a good tug to make sure it's secure. If you find any loose connections, re-do them.

Look for signs of overheating. Overheated wires can often be identified by their discolored or melted insulation. If you see any signs of overheating, turn off the power to the circuit immediately and investigate the cause. The problem could be a loose connection, an overloaded circuit, or a wire that's too small for the current.

Use a multimeter to test for continuity. A multimeter can be used to check the continuity of the circuit and identify any breaks in the wire. This can help you pinpoint the location of the problem.

When in doubt, call a qualified electrician. If you're not comfortable troubleshooting electrical problems yourself, it's always best to call a qualified electrician. They have the knowledge, skills, and tools to diagnose and repair electrical problems safely and effectively. They'll also be able to tell you if your spliced wires "Can you splice multiple wires together" are done properly and according to code!

FAQ

6. Frequently Asked Questions About Splicing Multiple Wires

Let's tackle some of those nagging questions you might have about splicing wires. Consider this your quick reference guide to electrical connections.

Q: Is it okay to just twist wires together and wrap them with electrical tape?A: While it might seem like a quick and easy solution, simply twisting wires together and taping them is generally not recommended, and often not up to code. It's not a mechanically secure connection, and the tape can degrade over time, potentially exposing the wires. Always use approved connectors like wire nuts or crimp connectors for a safe and reliable splice.

Q: Can I splice wires outside?A: Yes, you can splice wires outside, but you must use waterproof connectors or enclosures to protect the splice from moisture and corrosion. Regular wire connectors will not hold up well in outdoor conditions. Look for connectors specifically designed for outdoor use — they'll usually have a gel or sealant to keep water out.

Q: What if I need to splice different gauge wires together?A: Splicing different gauge wires is possible, but you need to be mindful of the circuit's overall current-carrying capacity. The splice should be protected by the lowest gauge wire's limit in the circuit. Use a wire connector that is rated for the range of wire gauges you are connecting. Always err on the side of caution and consult an electrician if you're unsure.

Q: How many wires can you splice together safely?A: The number of wires you can splice together safely depends on the wire connector's rating and the size of the electrical box. Each connector is designed for a specific range of wire sizes and number of wires. Check the connector's packaging for the maximum number of wires it can accommodate. Additionally, the electrical box needs to be large enough to accommodate all the wires, connectors, and devices inside it. Overcrowding an electrical box can create a fire hazard. There's always a limit when it comes to "Can you splice multiple wires together".

Q: What happens if I use the wrong size wire connector?A: Using the wrong size wire connector can lead to a loose or unreliable connection. If the connector is too small, it may not be able to accommodate all the wires, and if it's too large, the wires may not be held securely. A loose connection can create resistance, which can cause the wires to overheat and potentially start a fire. Always use the correct size connector for the number and gauge of wires you're connecting.

How To Splice Two Electrical Wires Together