Fantastic Tips About How To Waterproof A Splice

How To Make A Weatherproof Cable Splice Apogee Instruments, Inc.

Choosing Your Weapon: The Right Waterproofing Materials

Selecting the Optimal Solutions for Lasting Protection

The market offers a diverse array of materials designed to waterproof electrical splices, each with its unique strengths and applications. The key to success lies in selecting the material best suited for the specific environment and type of splice you are working with. From simple electrical tape to advanced heat-shrink tubing and specialized gel-filled connectors, understanding your options is the first step towards a truly waterproof connection.

For temporary or light-duty applications, high-quality electrical tape can provide a basic level of moisture resistance. However, it—s important to distinguish between standard electrical tape and specialized waterproofing tape, which often features a self-fusing rubberized composition for superior sealing. While convenient, tape alone rarely offers the long-term, robust protection required for outdoor or underground installations.

Heat-shrink tubing is a perennial favorite among professionals for its ease of use and excellent sealing properties. When heated, this tubing shrinks tightly around the splice, creating a snug, protective barrier against moisture, dust, and corrosion. Many varieties come with an adhesive lining that melts and flows, further enhancing the seal and providing additional strain relief. This method is particularly effective for creating durable, professional-looking connections.

For truly demanding environments, such as direct burial or areas prone to constant saturation, gel-filled connectors or epoxy potting compounds offer the ultimate in waterproofing. These solutions encapsulate the entire splice in a protective, dielectric medium, completely isolating it from water. While more involved to apply, they provide unparalleled long-term reliability and peace of mind in the harshest conditions. Your choice will largely depend on the level of exposure to moisture and the criticality of the connection.

The Art of the Seal: Step-by-Step Waterproofing Techniques

Mastering the Application for Impeccable Results

Once you—ve selected your waterproofing material, the next crucial step is proper application. Even the best materials will fail if not installed correctly. This section breaks down the general techniques for achieving a reliable, watertight seal, emphasizing precision and attention to detail. Remember, patience is a virtue when it comes to electrical work, and rushing can lead to costly mistakes.

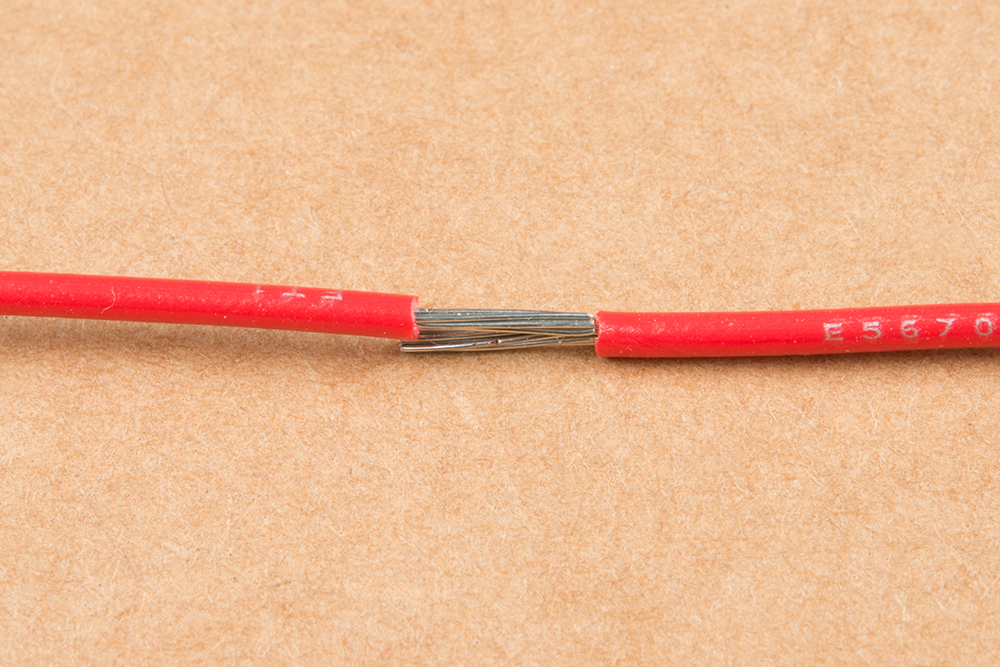

Before applying any waterproofing material, ensure the splice itself is correctly made and mechanically sound. This means clean, tightly twisted, or crimped wires. Any loose strands or poor connections will compromise the integrity of the splice, regardless of how well it—s waterproofed. Clean the wires thoroughly to remove any grease, dirt, or oxidation that could prevent proper adhesion or sealing of your chosen material. A clean surface is paramount for a lasting bond.

When using heat-shrink tubing, proper sizing is critical. The tubing should be large enough to slide over the splice easily but small enough to shrink tightly around it. After positioning the tubing over the splice, apply heat evenly with a heat gun (not an open flame, as this can damage the insulation or ignite materials). Rotate the tubing slowly to ensure uniform shrinkage, paying close attention to the ends to ensure a complete seal, especially if using adhesive-lined tubing where you want to see a small bead of adhesive extrude.

For gel-filled connectors or epoxy potting, follow the manufacturer—s instructions meticulously. These typically involve mixing two components and then injecting or pouring the mixture into a specially designed housing that encases the splice. Allow ample curing time as specified by the product. These methods create a solid, impenetrable barrier, making them ideal for truly submersible or buried applications. No matter the method, thoroughness in application is the cornerstone of effective waterproofing.

Common Pitfalls and How to Avoid Them

Steering Clear of Waterproofing Woes

Even with the right materials and techniques, certain mistakes can undermine your best efforts to waterproof an electrical splice. Being aware of these common pitfalls can save you time, money, and potential headaches down the line. A little foresight goes a long way in ensuring your connections remain dry and dependable.

One frequent error is underestimating the environmental conditions. What might be sufficient for an occasional splash might be wholly inadequate for constant immersion or prolonged exposure to humidity. Always consider the worst-case scenario for your specific installation and choose your waterproofing method accordingly. “Good enough” often isn—t when it comes to keeping water out of electrical connections.

Another common mistake is neglecting proper surface preparation. As mentioned earlier, clean wires are essential for adhesion and effective sealing. Skipping this step, or not cleaning thoroughly enough, can lead to poor adhesion of tapes or ineffective sealing of heat shrink, creating pathways for moisture to infiltrate. It—s a small step that yields significant dividends in the long run.

Overheating heat-shrink tubing, using too little or too much potting compound, or not allowing sufficient curing time for epoxies are also common blunders. Always adhere to the manufacturer—s recommendations for application and curing. Think of it like baking a cake—deviating from the recipe can lead to an undesirable outcome. Precision in application is just as vital as the quality of the materials themselves.

Finally, never assume that a waterproof connection is invincible. Regular inspection, especially for outdoor or exposed splices, is always a good idea. Look for signs of wear, cracking, or deterioration of the waterproofing material. Proactive maintenance can identify potential issues before they become serious problems, ensuring the continued safety and functionality of your electrical system.

How To Use Quick Splice Connectors Tap Into Your Vehicle's Main

Beyond the Basics: Advanced Considerations for Ultimate Protection

Elevating Your Waterproofing Game

For those seeking the pinnacle of protection, or for highly critical applications, there are additional considerations that can further enhance the waterproofing of electrical splices. These advanced techniques often involve combining multiple methods or utilizing specialized products designed for extreme conditions, taking your waterproofing efforts to the next level.

One such advanced consideration is the use of a layered approach. For instance, after making a mechanically sound splice, you might first apply a layer of adhesive-lined heat-shrink tubing, followed by an overwrap of self-fusing silicone tape. This multi-layered defense creates redundant barriers against moisture ingress, significantly increasing the reliability of the connection, especially in harsh environments where a single layer might eventually fail.

Another often overlooked aspect is strain relief. While not directly a waterproofing method, ensuring proper strain relief prevents wires from pulling out of the splice, which could compromise the waterproof seal. Cable glands and specialized connectors with built-in strain relief mechanisms are excellent for this purpose, distributing mechanical stress away from the delicate splice and its protective layers.

For applications where condensation is a concern, even within an otherwise sealed enclosure, consider incorporating desiccant packs. These small packets absorb moisture from the air, helping to maintain a dry internal environment around the splice. While not a direct waterproofing solution for the splice itself, they prevent the buildup of humidity that can lead to corrosion and eventual electrical failure over time.

Finally, in environments with extreme temperature fluctuations, selecting materials that can withstand these cycles without cracking or losing their sealing properties is crucial. Some waterproofing compounds are specifically formulated to maintain flexibility and integrity across a wide temperature range. Always check the product specifications for temperature ratings to ensure they meet the demands of your specific application, ensuring long-term performance under varying thermal conditions.

Frequently Asked Questions About Waterproofing Splices

Your Top Queries Answered for Watertight Connections

Got more questions bubbling up about keeping your electrical connections dry? You—re not alone! Here are some of the most common inquiries we hear when it comes to waterproofing splices, along with our expert insights to help you navigate the watery depths of electrical protection.

Q1: Can I just use regular electrical tape for outdoor splices?

A1: While regular electrical tape offers some initial insulation, it—s generally not sufficient for long-term outdoor waterproofing. It tends to degrade over time when exposed to UV light, temperature fluctuations, and moisture, leading to compromised protection. For reliable outdoor applications, it—s highly recommended to use specialized waterproofing tapes (like self-fusing silicone tape), heat-shrink tubing with adhesive, or gel-filled connectors for superior and lasting protection. Think of regular tape as a raincoat for a light drizzle, while true waterproofing is like a full submarine suit!Q2: How do I know if my splice is truly waterproof? Is there a test?

A2: For most DIY or general applications, a visual inspection is the primary test. Ensure the waterproofing material completely encapsulates the splice, with no gaps, cracks, or loose edges. For critical or commercial applications, some professionals might perform continuity and insulation resistance tests before and after waterproofing, and in some specialized cases, even submersion tests within a controlled environment (though this is rare for typical installations). The best indicator is a meticulously applied material and adherence to best practices. If it looks sealed and feels solid, you—re usually in good shape!Q3: What—s the biggest mistake people make when trying to waterproof a splice?

A3: The biggest mistake by far is inadequate surface preparation and rushing the application. Trying to waterproof a dirty, greasy, or poorly made splice is like trying to paint over rust—it simply won—t hold up. Ensure your wires are clean and your splice is mechanically sound before applying any waterproofing material. Secondly, skimping on the material or not applying it thoroughly (e.g., not properly heating heat-shrink tubing or not allowing potting compounds to fully cure) will lead to premature failure. Patience and precision are your best friends here!