Beautiful Work Info About Is VFD Output AC Or DC

VFD Control Wiring Diagram How To Wire A Variable Frequency

Unraveling the Mystery

1. Deciphering the VFD Signal

Let's dive right into the electrifying world of Variable Frequency Drives (VFDs). You're probably wondering, "Okay, so these VFD things control motor speeds, but what kind of juice are they actually spitting out? Is it AC or DC?" Well, the answer, my friends, is that the output of a VFD is AC — alternating current. But, it's not just any old AC; it's a specially crafted AC signal designed to make motors dance to your tune. It's like having a conductor for your electrical symphony. Think of it as tailored power, specifically designed to meet the needs of your motor.

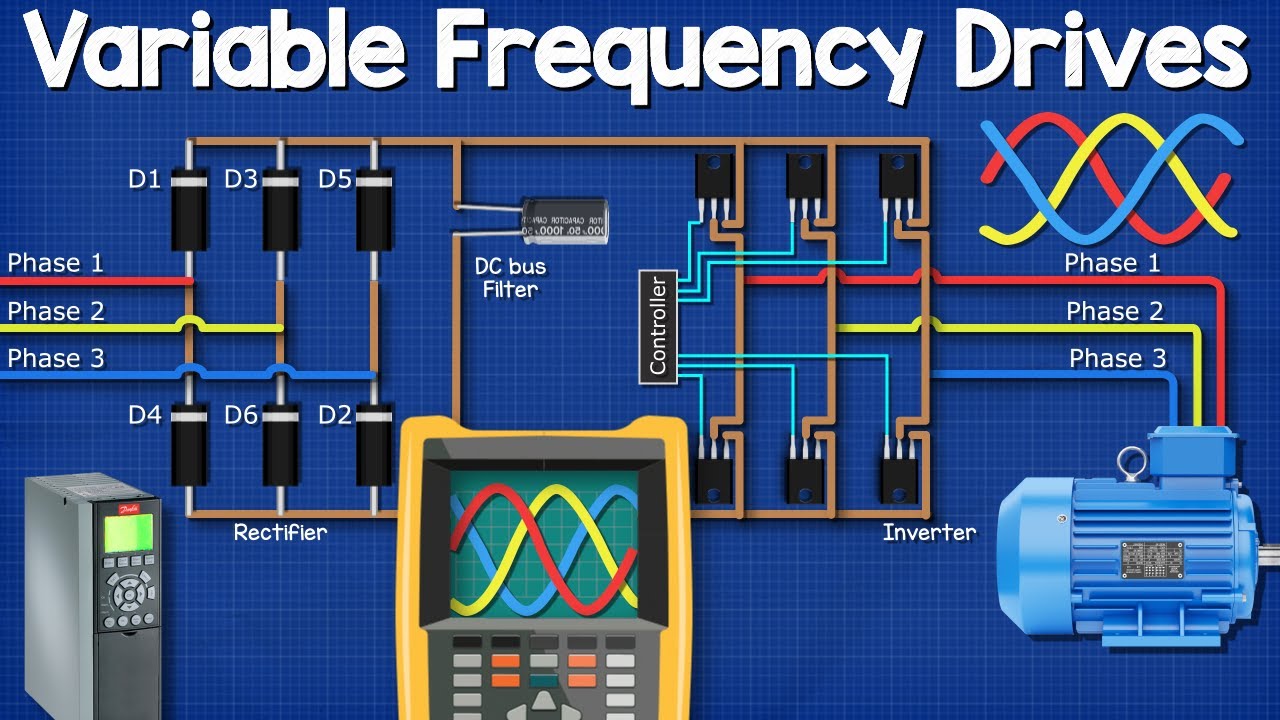

The VFD takes incoming AC power (usually from the mains), converts it to DC, and then cleverly inverts it back to AC, but with a twist. This twist is the adjustable frequency and voltage. By changing these parameters, the VFD can precisely control the speed and torque of the motor. It's like having a volume knob for your motor, giving you ultimate control over its performance. So yes, the final output is AC, but it's AC with superpowers.

Now, here's where it gets a little bit like magic. That DC stage is crucial. It's the secret ingredient in the VFD's recipe. It acts as a kind of "power reservoir," smoothing out the incoming AC and providing a stable platform for the inverter section. Without this DC link, the VFD wouldn't be able to create that perfectly shaped AC waveform that your motor craves. Think of it as the calm before the (electronically controlled) storm!

Think of it like this: the original AC power is a raw, unshaped block of marble. The VFD is the sculptor. It first breaks down the marble into smaller pieces (converting to DC), then meticulously shapes and reforms them into a beautiful statue (the variable frequency AC). Its a process of controlled transformation, and that transformation is the key to unlocking efficient motor control.

The Journey of Electricity

2. Understanding the Conversion Process

So, we've established that VFDs output AC. But the real magic happens in the process of getting there. The power undergoes a fascinating transformation, a veritable electrical metamorphosis, before it reaches the motor. Let's break down this exciting journey, step by step.

First, the VFD receives the incoming AC power, which is then fed into a rectifier. The rectifier's job is to convert the AC power into DC power. Think of it like a one-way street for electrons, ensuring they only flow in one direction. This is typically achieved using diodes, which act as electrical check valves, blocking current flow in one direction while allowing it in the other. It's the first, crucial step in shaping the power to your will.

Next, the DC power passes through a filter capacitor bank. These capacitors smooth out the DC voltage, reducing ripple and providing a stable DC bus voltage. Think of it as a water reservoir, storing energy and releasing it smoothly, ensuring a consistent flow of power. This stable DC voltage is essential for the inverter stage to function correctly.

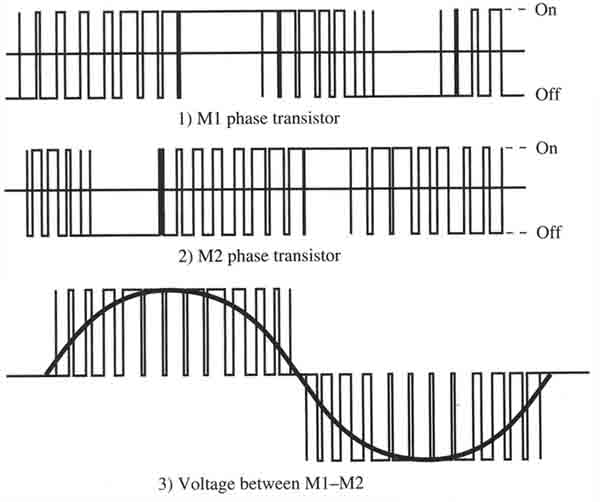

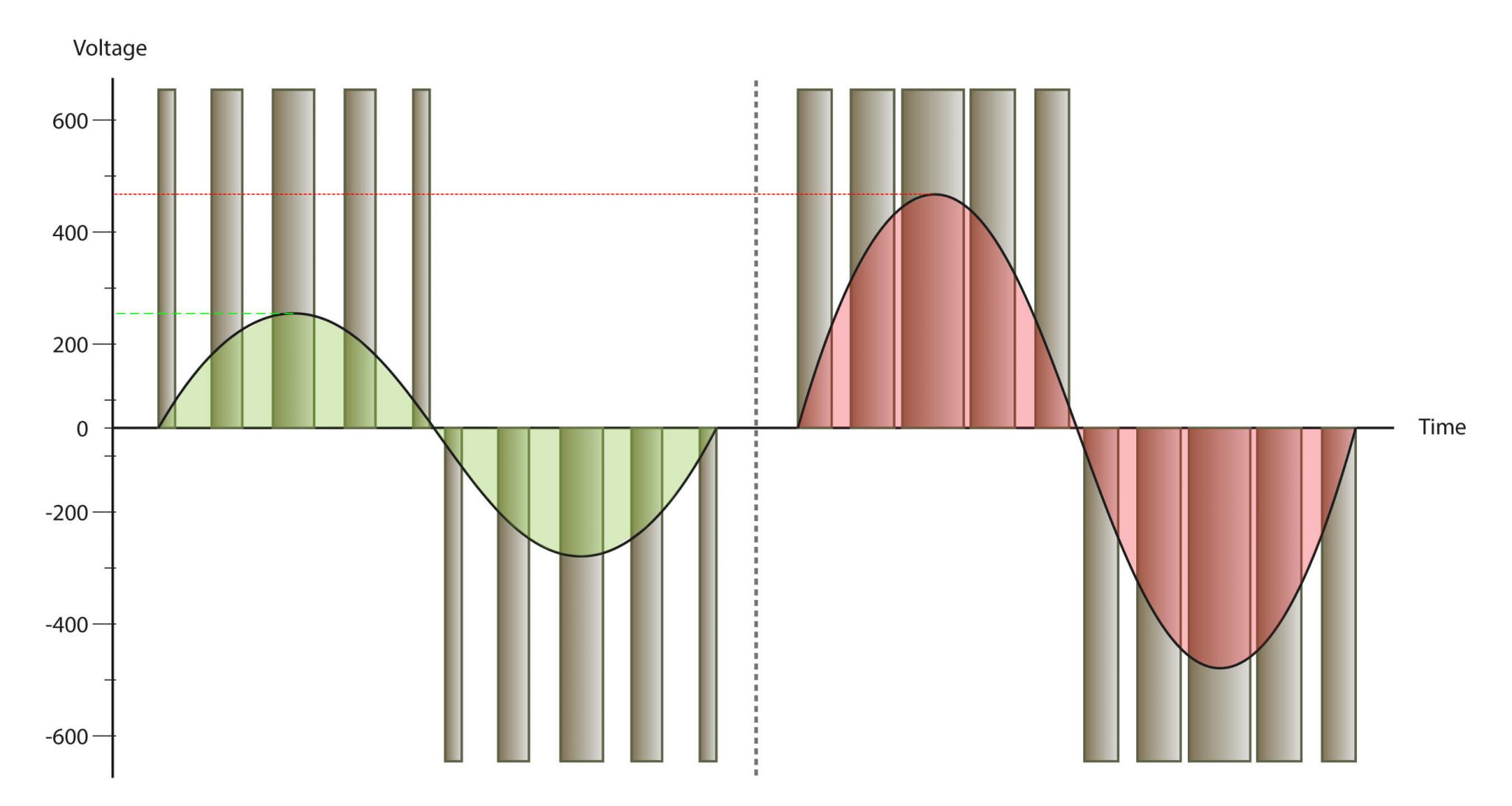

Finally, the DC power is fed into the inverter section, which uses a series of electronic switches (typically IGBTs or MOSFETs) to rapidly switch the DC voltage on and off, creating an AC waveform. By controlling the switching frequency and pulse width, the inverter can generate an AC voltage with a specific frequency and amplitude. This allows the VFD to control the motor's speed and torque with high precision. It's like a finely tuned instrument, creating the perfect electrical symphony for your motor.

What Is A VFD?

Why AC Output Matters

3. The Benefits of Variable Frequency AC

Okay, so the VFD spits out AC. Big deal, right? Wrong! The fact that it's adjustable AC — that's the real kicker. This variable frequency capability unlocks a whole new world of motor control and efficiency. We're not just talking about turning a motor on and off; we're talking about orchestrating its performance with pinpoint accuracy.

By adjusting the frequency of the AC output, the VFD can directly control the speed of the motor. This is crucial for applications where precise speed control is required, such as conveyor belts, pumps, and fans. Imagine a conveyor belt that needs to run at different speeds depending on the product being transported. With a VFD, you can easily adjust the speed to match the needs of the application, optimizing throughput and efficiency. It's like having a dimmer switch for your motor, giving you complete control over its performance.

Furthermore, VFDs improve energy efficiency by reducing power consumption during periods of low demand. Traditional motor control methods often rely on throttling valves or dampers to control flow, which wastes energy. With a VFD, you can reduce the motor's speed to match the actual demand, saving energy and reducing operating costs. Its like turning down the thermostat when you leave the house — a simple way to save energy and money.

Beyond speed and efficiency, the tailored AC output allows for smoother starting and stopping of motors, reducing mechanical stress and extending their lifespan. No more jerky starts and stops! The VFD gently ramps up and down the motor's speed, preventing sudden jolts and vibrations. This translates to less wear and tear on the motor and connected equipment, resulting in longer equipment life and reduced maintenance costs. It's like giving your motor a gentle massage instead of a sudden shock.

Variable Frequency Drives Explained VFD Basics IGBT Inverter YouTube

Spotting the Differences

4. Where Each Type Excels

While VFDs are all about that glorious AC output, it's important to remember that both AC and DC have their own special places in the world of electricity. Thinking they're interchangeable is like thinking you can use a hammer to cut a piece of wood. Sure, you could try, but you'd be much better off with a saw!

AC power is the king of long-distance transmission. It's the power that comes out of your wall socket and powers most of your home appliances. Why AC for long distances? Because it's easily stepped up to high voltages for efficient transmission over power lines and then stepped down again for safe use in homes and businesses. Think of it like a high-speed highway for electricity, allowing it to travel vast distances with minimal loss.

DC, on the other hand, is more suited for applications like batteries, solar panels, and electronic devices. Batteries store energy in DC form, and solar panels generate DC electricity. Many electronic devices also require DC power to operate, which is why you have those little power adapters that convert AC to DC. It's the preferred choice when you need a stable, consistent voltage for sensitive electronic components. Think of it as a gentle stream, providing a steady and reliable source of power.

So, while a VFD ultimately delivers AC to your motor, it cleverly uses both AC and DC in its internal workings to achieve precise and efficient motor control. It's a testament to the versatility and power of electrical engineering! Its important to understand which power type is best suited for your particular needs. Choosing the wrong type can lead to inefficiency, damage, and even safety hazards.

VFD Variable Frequency Drive Working With Block Diagram

Troubleshooting VFD Output Issues

5. Common Problems and Solutions

Even with all their wizardry, VFDs can sometimes throw a curveball. If your motor isn't behaving as expected, the problem might lie in the VFD's output. It's always wise to consult with qualified professionals to fix or troubleshoot electric issue. Here are a few common issues and how to approach them. Because messing with electricity when you're not qualified can be a shocking experience...literally!

One common issue is a distorted AC output waveform. This can be caused by a variety of factors, including faulty components within the VFD, improper wiring, or excessive electrical noise. A distorted waveform can lead to reduced motor performance, increased heat, and even damage to the motor. Checking the input power for stability and consulting the VFD manual are good starting points.

Another common problem is overvoltage or undervoltage on the AC output. This can be caused by fluctuations in the input power supply or by incorrect VFD settings. Overvoltage can damage the motor and VFD, while undervoltage can cause the motor to stall. Carefully reviewing the VFD parameters and ensuring they match the motor's specifications is essential.

Sometimes, the issue isn't the waveform itself, but the frequency or voltage being delivered. If the VFD isn't outputting the correct frequency, the motor speed will be incorrect. If the voltage is too low, the motor may not have enough torque. Ensuring the VFD is properly programmed for the motor and application is critical.

Always remember that working with electricity can be dangerous. If you're not comfortable troubleshooting VFD output issues yourself, consult a qualified electrician or VFD technician. They have the knowledge and experience to diagnose and repair these problems safely and effectively. Its better to be safe than sorry when dealing with potentially hazardous electrical equipment.

FAQ

6. Get the Facts Straight

Still scratching your head? No problem! Here are a few frequently asked questions to clear up any lingering doubts about VFDs and their AC output.

Q: Can I use a VFD to convert DC power to AC?

A: Not directly. While VFDs have a DC link internally, they are designed to take AC input, convert it to DC, and then invert it back to AC with variable frequency and voltage. To convert DC to AC, you would typically use a dedicated inverter.

Q: What happens if I connect a DC motor to a VFD's AC output?

A: That's generally not a good idea! DC motors are designed to run on DC power, and applying AC voltage to them can cause overheating, damage, or even failure. Stick to using AC motors with VFDs for best results.

Q: Are all VFDs compatible with all AC motors?

A: Not necessarily. It's important to ensure that the VFD is properly sized for the motor's voltage, current, and horsepower ratings. Using an undersized VFD can lead to overheating and damage, while using an oversized VFD can be inefficient. Always consult the VFD and motor specifications to ensure compatibility.