Stunning Tips About Can I Use Stranded Wire For Ground

Stranded Wire for Grounding

1. Is Stranded Wire Safe for Grounding Purposes?

So, you're staring at a spool of stranded wire and wondering if it's the right stuff for your grounding project? It's a fair question! Let's break down whether you can confidently use stranded wire for ground connections without accidentally recreating a scene from a bad electrical safety video. After all, nobody wants a surprise jolt!

The short answer is: yes, generally, you can use stranded wire for grounding. However, and this is a big however, there are a few things to consider. Think of it like choosing between a regular coffee and an espresso. Both are coffee, but they deliver caffeine in different ways, right? Stranded and solid wire both conduct electricity, but their characteristics matter for specific applications.

First, it's essential to check your local electrical codes and regulations. These codes are like the recipe book for safe wiring. They might have specific requirements for grounding conductors, including the allowable types of wire. What's acceptable in one jurisdiction might not be in another. It is always better to safe than sorry.

Secondly, remember that not all stranded wire is created equal. The gauge (thickness) of the wire matters. A thicker wire will handle a larger fault current, providing a more robust path to ground. Choosing the correct gauge is crucial for safety, just like wearing the right size shoes matters to confort. Also, quality matters! Ensure you are getting electrical-grade wire that meets industry standards. There's no point in cutting corners when safety is on the line. Cheap wire could potentially lead to a compromised ground.

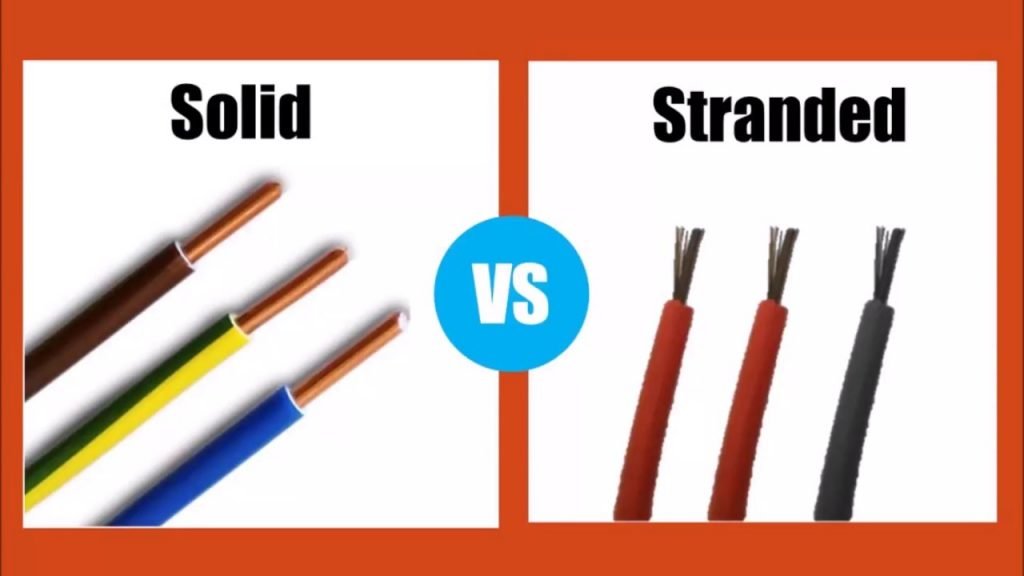

Solid vs. Stranded

2. Comparing Wire Types for Grounding Applications

Now, let's have a little face-off between solid and stranded wire for ground. Both have their strengths and weaknesses when it comes to grounding. Think of it like a superhero battle: each has unique abilities.

Solid wire is generally cheaper and easier to work with for simple runs where flexibility isn't a concern. It's like the reliable, no-frills workhorse. However, solid wire can be more prone to breakage if it's repeatedly bent or subjected to vibration. Imagine bending a paperclip back and forth until it snaps — that's what can happen to solid wire over time.

Stranded wire, on the other hand, is more flexible and resistant to fatigue. This makes it a better choice for applications where the wire needs to be moved or bent, such as in appliances or machinery. Its like the gymnast, capable of bending and flexing without breaking. The increased surface area of the individual strands can also offer slightly better conductivity in some cases. However, stranded wire is typically more expensive than solid wire and requires proper termination to ensure a solid connection. It's like needing special equipment to ensure the gymnast lands safely.

For grounding, the choice between solid and stranded often comes down to the specific application and local codes. In many residential settings, solid wire is commonly used for grounding because it's cost-effective and readily available. But in industrial settings or applications where vibration is a concern, stranded wire is generally preferred for its increased durability. Always refer to your local electrical codes or consult with a qualified electrician to determine the best type of wire for your specific needs.

Grounding Best Practices

3. Ensuring Proper Grounding with Stranded Wire

Okay, so you've decided stranded wire for ground is the way to go. Excellent! But the job's not over yet. Proper termination and connection are absolutely critical for ensuring a safe and effective ground. Think of it like building a house; even with the best materials, a weak foundation will cause problems down the road.

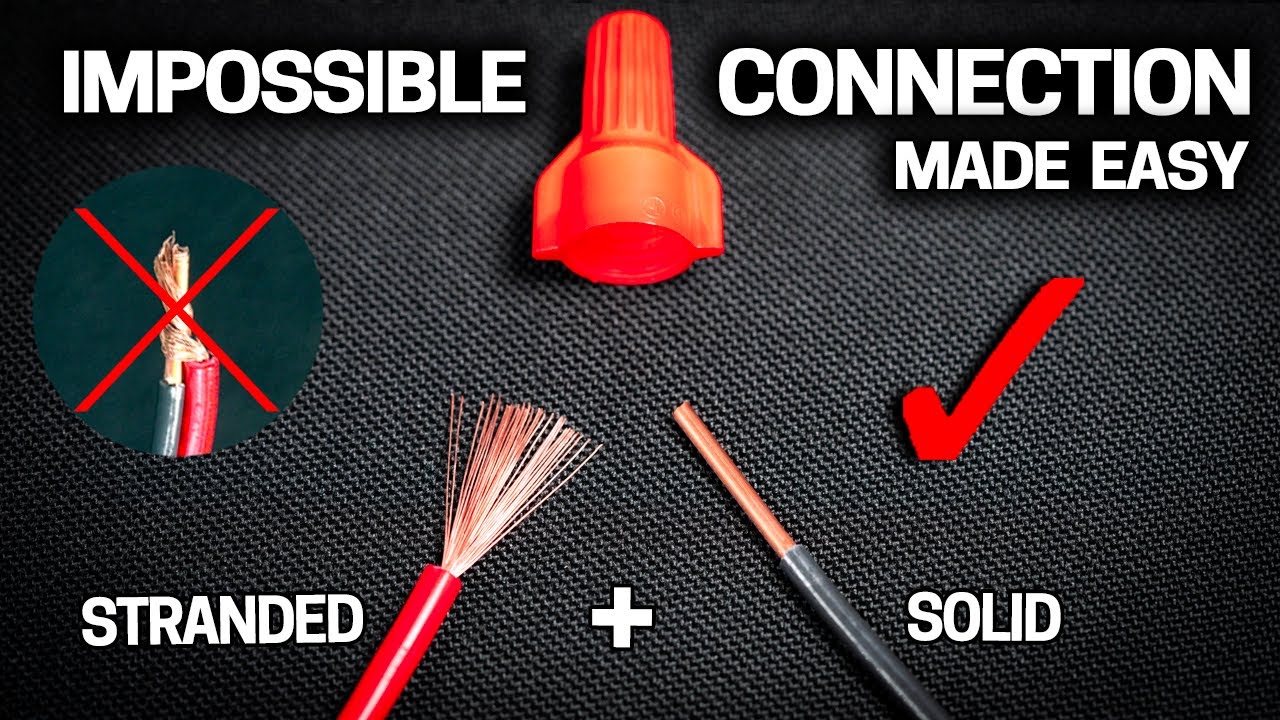

First, use the correct type of connectors. These are designed to securely grip the strands of wire and provide a low-resistance connection. Avoid simply twisting the wires together and hoping for the best — that's a recipe for disaster! Crimp connectors, screw terminals, and wire nuts are all common options, but make sure they're rated for the size and type of wire you're using. It's like using the right size wrench for a bolt; using the wrong one can damage the connection.

Second, ensure the connections are clean and free of corrosion. A dirty or corroded connection can significantly increase resistance, reducing the effectiveness of the ground. Before making a connection, clean the wire with a wire brush or sandpaper. You can also apply an antioxidant compound to prevent future corrosion. Think of it as cleaning your glasses — you'll see much better afterwards!

Third, tighten all connections securely. A loose connection can create a fire hazard. Use a torque screwdriver to tighten screw terminals to the manufacturer's specifications. Regularly inspect your grounding connections to ensure they remain tight and corrosion-free. It's like checking the tires on your car before a long trip; it's a simple precaution that can prevent big problems down the road. These steps are critical for safety, so do not take them lightly.

Stranded Wire & Braids Types, Applications Benefits

Common Grounding Mistakes

4. Preventing Grounding Errors with Stranded Wire

Even with the best intentions, it's easy to make mistakes when working with electrical wiring. Let's shine a spotlight on some common grounding errors to help you steer clear of them when you use stranded wire for ground.

One common mistake is using undersized wire. Remember, the grounding conductor needs to be able to safely carry the maximum fault current. Using a wire that's too small can cause it to overheat and potentially melt, creating a fire hazard. Always consult the electrical code to determine the correct wire size for your application. It's like wearing shoes that are too small; it's uncomfortable and potentially dangerous.

Another mistake is improper bonding. Bonding is the process of connecting all metal parts of an electrical system together to create a common ground. This includes things like metal conduits, enclosures, and equipment frames. If these parts aren't properly bonded, they can become energized during a fault, posing a shock hazard. Ensure all metal parts are securely connected to the grounding system. It's like connecting all the pieces of a puzzle; if one piece is missing, the picture isn't complete.

Neglecting corrosion is another issue. Over time, grounding connections can corrode, increasing resistance and reducing effectiveness. Regularly inspect your grounding connections for signs of corrosion and clean or replace them as needed. Applying an antioxidant compound can help prevent corrosion. It's like brushing your teeth; regular maintenance is essential for long-term health.

Finally, a very common error is failing to properly ground appliances and equipment. Most appliances and equipment have a grounding wire or terminal that needs to be connected to the grounding system. This provides a safe path for fault current in case of a short circuit. Always follow the manufacturer's instructions for grounding appliances and equipment. It's like buckling your seatbelt; it's a simple precaution that can save your life.

Can You Use Stranded Wire For Outlets

Grounding FAQ

5. Frequently Asked Questions About Stranded Wire and Grounding

Still have some lingering questions about stranded wire for ground? No problem! Let's tackle some frequently asked questions to clear up any remaining doubts.

Q: Can I use different gauges of stranded wire for grounding in different parts of my system?A: Generally, no. The grounding conductor must be sized according to the overcurrent protection device (fuse or circuit breaker) protecting the circuit. It's best practice to use the same gauge throughout the grounding system for consistency and to ensure adequate fault current capacity. It's like making a smoothie; you need the right proportion of each ingredient for the best taste.

Q: Is it okay to mix solid and stranded wire in a grounding system?A: While it's generally acceptable, it's best to avoid mixing solid and stranded wire within the same continuous run of grounding conductor. Transitioning between the two types can create a point of potential weakness and increase resistance. If you must transition, use appropriate connectors designed for mixing wire types. Think of it as speaking two different languages; you need a translator to effectively communicate.

Q: How often should I inspect my grounding system?A: Grounding systems should be inspected regularly, especially in harsh environments or applications where vibration is present. A visual inspection at least once a year is a good starting point. Look for signs of corrosion, loose connections, or damaged wiring. If you notice any problems, address them immediately. It's like getting a regular checkup; early detection can prevent serious problems.

Q: What happens if my ground wire isn't connected properly?A: A poorly connected or missing ground wire creates a serious safety hazard. In the event of a short circuit or fault, electricity will seek an alternative path to ground, potentially through a person touching the faulty appliance or equipment. This can result in severe electric shock or even death. Always ensure grounding connections are properly made and tested. It's the difference between a safe outlet, and a disaster waiting to happen.