Lessons I Learned From Tips About What Controls A VFD

Unlocking the Secrets

1. The Brains Behind the Operation

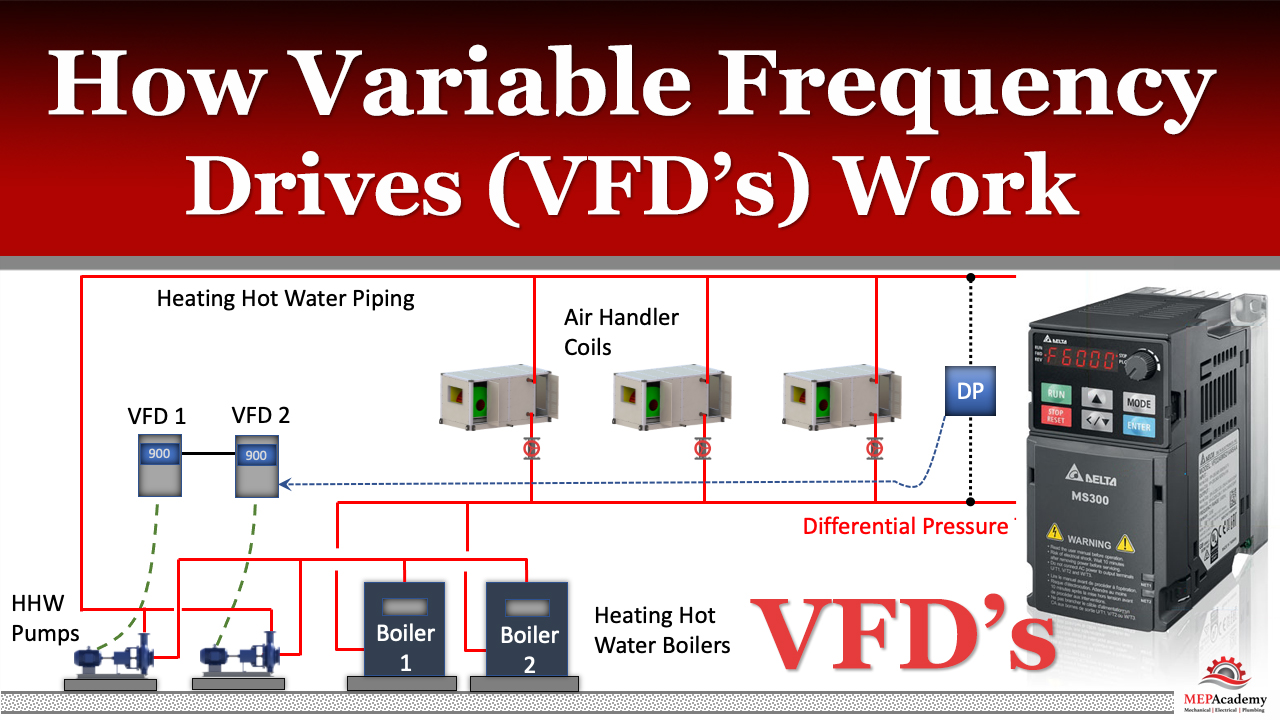

Ever wondered what makes those Variable Frequency Drives (VFDs) tick? They're not just spinning motors faster or slower on a whim! There's a whole control system working diligently behind the scenes. Think of it like the conductor of an orchestra, ensuring every instrument plays its part in harmony. In this case, the 'instruments' are the motor and the power it delivers, and the 'conductor' is the VFD's control system.

At its core, what controls a VFD is a sophisticated blend of hardware and software, working together to manipulate the frequency and voltage supplied to an electric motor. Its more than just a simple dial to turn up the speed; we're talking about precisely calibrated electronic components and complex algorithms that dictate how the motor behaves. Imagine the control system is like a skilled chef meticulously adjusting the heat under a pot to prevent it from boiling over — only with electricity and motors!

The control system's primary job is to take your desired motor speed (the 'setpoint,' as engineers like to say) and translate that into the appropriate electrical signals. This involves taking feedback from the motor itself — think of it as the motor reporting back on its performance — and constantly adjusting the output to match the desired speed. The better the control system, the smoother and more efficient the motor operates. It's the equivalent of having a smart thermostat that learns your preferences and adjusts the temperature accordingly without you even noticing.

But what exactly makes up this control system? Let's dive a little deeper into the key components that allow the VFD to do its magic. It's a journey into the inner workings, but hopefully, we can keep it relatively painless!

2. Peeking Under the Hood

3. The Usual Suspects

Now, let's talk about the key players that make up the VFD's control system. We're talking about things like rectifiers, inverters, and microprocessors — sounds intimidating, right? Don't worry, we'll break it down into bite-sized pieces. You might not become an electrical engineer overnight, but you'll at least be able to hold your own in a conversation about VFDs at your next dinner party (assuming that's a thing!).

First up, the rectifier. Think of the rectifier as a translator. It takes the incoming AC power and converts it into DC power. It's like changing dollars into euros for your European vacation. This DC power then gets stored in capacitors, which act like batteries, holding onto that power until it's needed. They smooth out any ripples in the DC voltage, ensuring a stable power source.

Next, the inverter. This is where the magic truly happens. The inverter takes that stored DC power and converts it back into AC power, but with one crucial difference: it can control the frequency and voltage of that AC power. This is how the VFD controls the speed of the motor. It's like having a volume knob for your motor's speed! This control is achieved using sophisticated switching techniques with transistors, allowing for extremely precise adjustments.

Finally, the microprocessor. This is the brains of the operation. It monitors the entire system, takes input from sensors, and calculates the optimal frequency and voltage to send to the motor. It's constantly adjusting the output based on feedback from the motor, ensuring that it's running at the desired speed and torque. You can think of it as the conductor, making sure all the 'instruments' — rectifier, inverter, motor — are playing in perfect sync.

4. Control Methods

5. Different Strokes for Different Folks

Not all VFD control methods are created equal! There's a whole range of options, each suited for different applications and performance requirements. Its like choosing between different types of engines for a car: some are built for fuel efficiency, others for raw power, and some strike a balance between the two. Understanding these options is key to getting the most out of your VFD.

One common method is called V/Hz control (or volts per hertz control). This is the simplest and most widely used method, particularly for general-purpose applications. It maintains a constant ratio between the voltage and frequency supplied to the motor. It's easy to implement and works well for many applications where precise speed control isn't critical. Think of it as cruise control for your motor, keeping it running at a relatively consistent speed.

For more demanding applications, vector control comes into play. This method provides much more precise control over the motor's torque and speed. It uses sophisticated mathematical models to estimate the motor's internal parameters and then adjusts the voltage and frequency accordingly. Its like having a GPS system for your motor, knowing exactly where it is and where it needs to be at all times.

Another option is direct torque control (DTC). This method directly controls the motor's torque by adjusting the voltage and frequency. It's even more advanced than vector control and provides extremely fast response times. It's like having a super-responsive steering wheel for your motor, allowing you to make quick and precise adjustments.

6. External Factors

7. It's Not Just About the Internals

While the internal control system is undoubtedly important, don't forget about the external factors that can influence a VFD's performance. These external factors can be anything from the ambient temperature to the load on the motor, and even the type of power supply. Neglecting these factors can lead to suboptimal performance, or even damage to the VFD or motor.

One of the most important external factors is the ambient temperature. VFDs generate heat, and excessive heat can shorten their lifespan and reduce their efficiency. Therefore, it's crucial to ensure that the VFD is properly cooled, either through natural convection or forced air cooling. Think of it like preventing your laptop from overheating by using a cooling pad. Proper ventilation is key to keeping your VFD running smoothly.

The load on the motor also plays a significant role. Overloading the motor can cause the VFD to work harder, leading to increased heat and stress on the components. This can shorten the VFD's lifespan and even cause it to fail. It's like asking your car to tow a trailer that's too heavy; it'll put a strain on the engine and transmission.

Finally, the quality of the power supply can also affect the VFD's performance. Voltage fluctuations or power surges can damage the VFD's sensitive electronic components. Therefore, it's important to ensure that the power supply is stable and reliable. Think of it like protecting your computer from power surges with a surge protector. A stable power supply is essential for reliable operation.

8. The Human Element

9. Taking Command

Ultimately, the control of a VFD often comes down to the user. The user interface and control panels allow you to set parameters, monitor performance, and troubleshoot any issues. A well-designed user interface can make all the difference in optimizing your VFD's performance. Think of it like the dashboard of your car; it provides you with the information you need to operate the vehicle safely and efficiently.

Modern VFDs often come with sophisticated control panels that allow you to adjust a wide range of parameters, such as motor speed, acceleration, and deceleration. These parameters can be adjusted to optimize the motor's performance for specific applications. It's like fine-tuning the settings on your camera to capture the perfect photo. Precise control over the VFD's parameters allows you to tailor its performance to your exact needs.

Many VFDs also have built-in monitoring capabilities that allow you to track the motor's performance in real time. This can help you identify potential problems before they become serious. It's like having a health monitor for your motor, alerting you to any signs of trouble. Monitoring performance allows you to proactively address any issues and prevent costly downtime.

And of course, there are also safety features. Many VFDs have built-in safety features, such as overload protection and short-circuit protection. These features help to protect the VFD and the motor from damage. Think of it like having a seatbelt in your car; it helps to protect you in the event of an accident. Safety features are crucial for ensuring the safe and reliable operation of your VFD.